Oskar Olofsson

Located in Stockholm, Sweden, our office provides an array of global consulting services, including cutting-edge digital tools for visual lean management, comprehensive training programs, and accessible, reader-friendly books on the subject.

2026-02-08 - OEE system - or paper and a pencil?

2026-01-09 - What I have learned on the flight and bus about leadership

2025-12-05 - How to create a production strategy

2025-10-11 - Lean in the process industry

At WCM Consulting AB, we're committed to your success with Lean and World-Class Manufacturing strategies.

Adhering to our bespoke "Lean Change Process" (refer to the illustration), we seamlessly blend strategic thought leadership, in-depth classroom training, and on-site, hands-on coaching.

Operating out of our Swedish headquarters, we provide globally-reaching consulting and training services, facilitated by our expansive international network.

WCM Consulting AB provides bespoke in-house training – a crucial component of any improvement initiative.

Setting us apart from traditional training methods is our commitment to providing more than just theoretical knowledge. All our training sessions are delivered on-site at your premises, allowing for a hands-on experience as we jointly apply techniques to enhance your work processes and optimize the workplace layout in practice.

As an outcome of our training programs, you will have robust, proven action plans, measurable goals, and a team that is dedicated and well-equipped. To ensure successful transformation, we often supplement the training with additional days of consultant support.

The 5S training is our most sought-after course. Conducted on your premises, it involves training all personnel and implementing one 5S step each month.

Read more

This two-day training session focuses on a specific production section or individual machine. Theoretical instruction is intertwined with practical analysis of your equipment and existing working methods, resulting in actionable plans, checklists, and new work standards.

Read more

Our Standardized Work training is a one or two-day session that harmoniously blends theoretical studies with practical exercises, offering a comprehensive learning experience.

Succeeding With 5S

Order from Amazon.com

.webp)

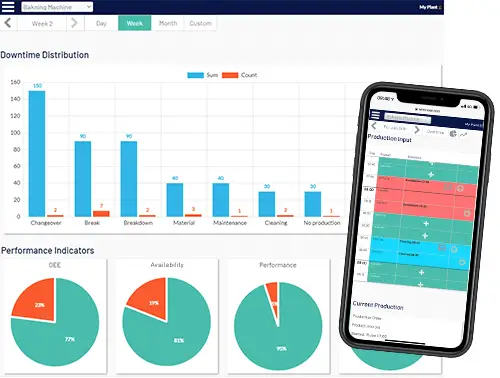

A Visual Management Platform

A stand-alone software for OEE/TAK

Oskar Olofsson is a distinguished expert in efficient production, bringing over 20 years of experience in assisting reputable companies to achieve their goals.

Through his innovative application of Lean methods and engaging change management processes, he not only enhances profitability but also transforms motivations and attitudes for the better.

Oskar has penned two popular books on the subject and is frequently sought after as an inspiring speaker.

Contact